Tilting Disc Check Valve

offers unrivaled versatility and reliability while providing a significant cost savings over the life of the valve

Valve disc automatic opening and closing upon pipeline flow and pump operation status.

Energy efficient, non-slam closing

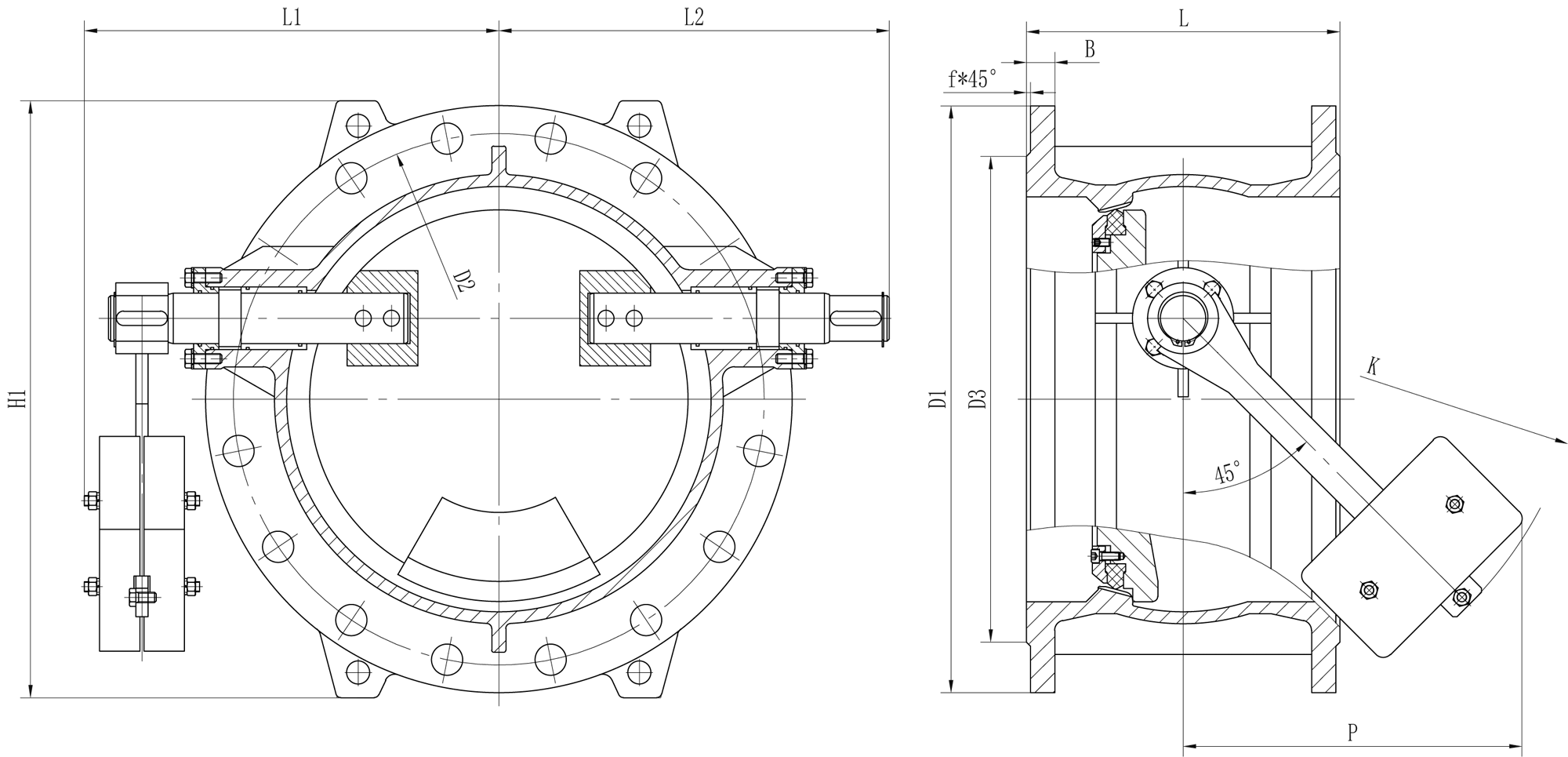

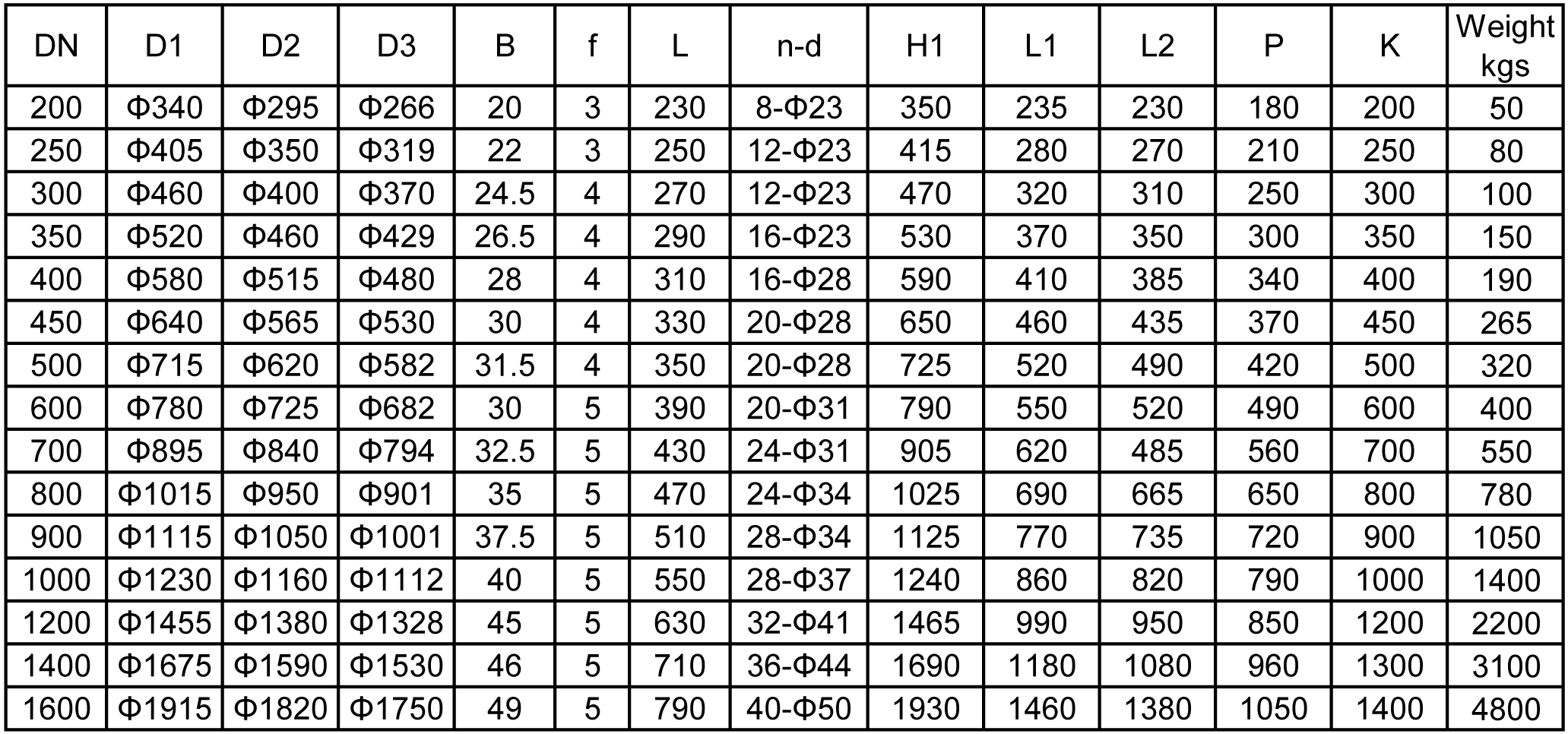

Valve design to EN593, EN 12334

Flange to EN 1092, BS4504, DIN2501, ISO7005, ASME B16.5, ASME B16.1, AWWA C207, AS4087

Face to face length to EN 558-1 / ISO 5752 series 14

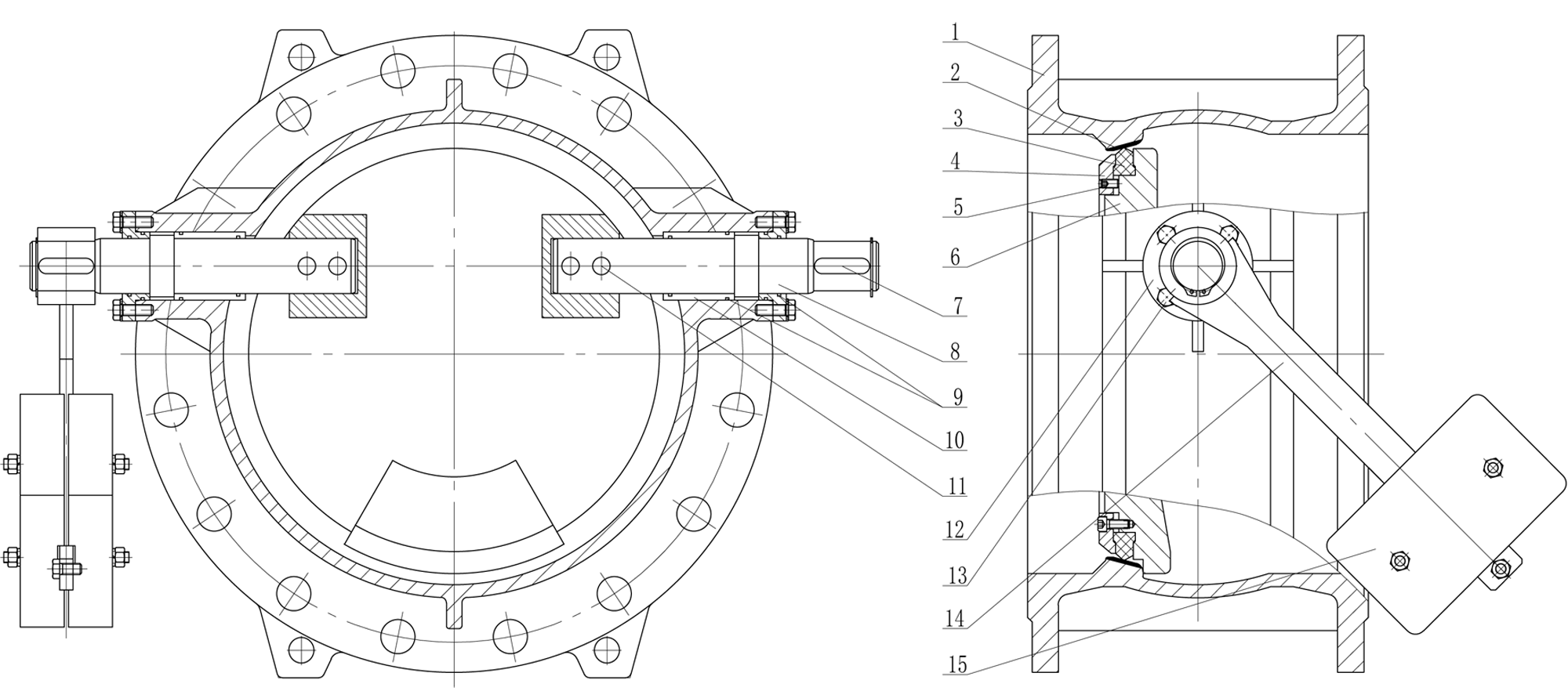

| No | Part name | Material | Remarks |

| 1 | Valve body | Ductile iron | GJS500-7(GGG50),GJS400-15(GGG40) |

| 2 | Body seat | Stainless steel | SS308,SS309lsi,SS304,SS316 welded |

| 3 | Disc seal ring | Rubber | EPDM, NBR,FKM, Silastic |

| 4 | Reainer ring | Stainess steel | 1.4301(SS304), 1.4401(SS316),1.4571(SS316Ti) |

| 5 | Screw | Stainess steel | A2-70(SS304), A4-70(SS316) |

| 6 | Valve disc | Ductile iron | GJS500-7(GGG50),GJS400-15(GGG40) |

| 7 | Key | Stainess steel | 1.4021(SS420) |

| 8 | Valve shaft | Stainess steel | 1.4021(SS420), 1.4057(SS431), 17-4PH(SS630) |

| 9 | O ring | Rubber | EPDM, NBR |

| 10 | Shaft bearing | Bronze | |

| 11 | Pin | Stainess steel | 1.4021(SS420), 1.4057(SS431), 17-4PH(SS630) |

| 12 | Shaft cover | Carbon steel | 1.0038(S235JR) |

| 13 | Bolt | Stainess steel | A2-70(SS304), A4-70(SS316) |

| 14 | Lever | Carbon steel | 1.0038(S235JR) |

| 15 | Counterweight | Carbon steel | 1.0038(S235JR) |

Other materials such as carbon steel, st. steel, duplex SS are available on request.

Tilting Disc Check Valve

offers unrivaled versatility and reliability while providing a significant cost savings over the life of the valve

Valve disc automatic opening and closing upon pipeline flow and pump operation status.

Energy efficient, non-slam closing

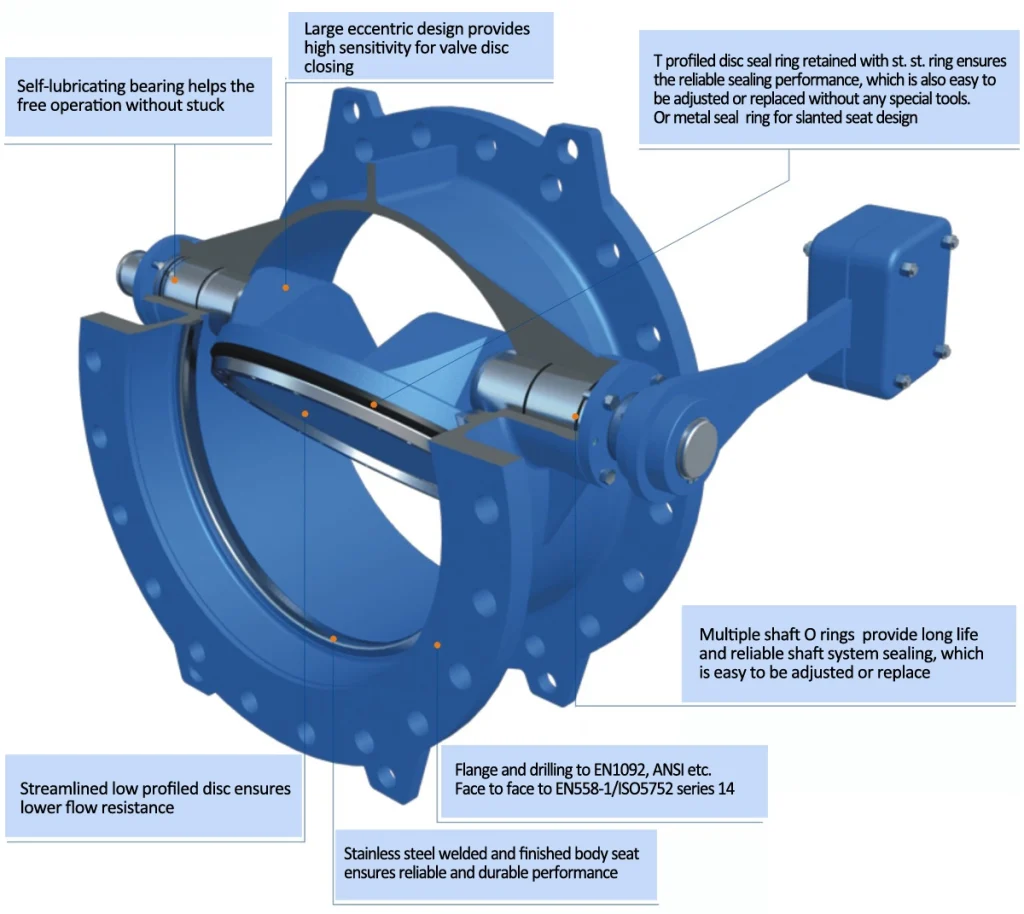

This kind of butterfly valve has the unique advantages:

– Keeping the main valve closed and bypass valve open. That can maintain minimum flow across the valve to avoid water stagnancy and maintain water quality.

– Equalize the pressure across the valve to enable manual opening in case of power unavailability.

BFV-02-QJ Rubber lined Butterfly Valve, internally with ebonite lining of thickness 3mm or 5mm.

The typical applications of this type of butterfly valves are chemical plants, sea water treatment, desalination projects, nuclear power plants, water treatment, TSE, sewage etc.

Rubber-Seated Butterfly Valves to AWWA C504, designed for drink water, sea water, cooling water etc. NSF/ANSI 61 approval is available.

Design is rated for B valves (max. flow velocity 16ft/sec-4.9m/sec), and absolutely compliance with the requirements in min. shaft diameter, min. body shell thickness and actuator test cycles, workshop testing and Proof-of-design tests etc.